We produce high quality classical wooden propellers for light aircrafts, flexwing microlights, paramotors and souvenir propellers. We are calculate and manufacture propellers for any flying vehicle and power plant.

We have been producing wooden propellers since 1990.

During this time we have done hundreds of screws that are installed on different planes, trikes, Airboats and snowmobile.

They are hand made by the classical technology that was used 100 years ago.

We usually use beech, ash, oak to ensure high strength and durability.

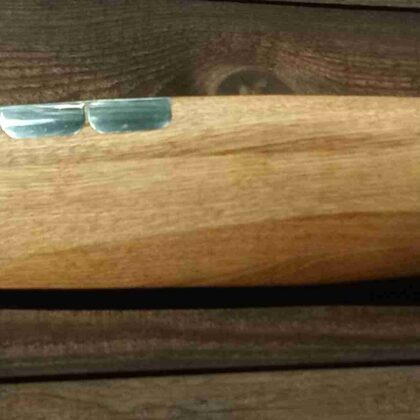

To increase the durability and moisture resistance of the surface we use glued fiberglass.

To increase the resistance to wear and resistance to damage to the front edge of the blade is protected by stainless steel.

To speed up and reduce the cost of production some of the propellers are made of pine.

These propellers are cheaper.

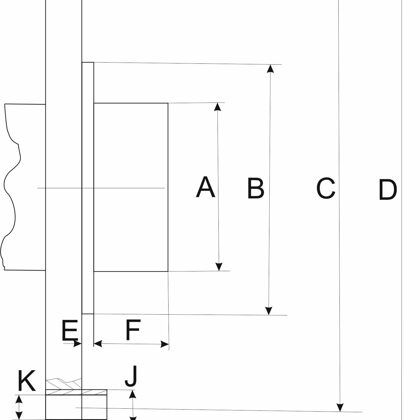

You can purchase propeller directly over the internet, sending us an email with your details and those of the propeller you need, its diameter, pitch, which way it rotates (to the right or left looking in the flight direction), mounting bolts & if the propeller is pull (at the front) or push (at the rear), for example: pull, mounting Rotax 6xM8 in 75 mm.

Alternatively, if you don't know exactly what propeller you need, give us the fullest possible information of the aircraft (cruising speed), of the engine (power, cubic capacity, RPM), and of the reduction gear (mechanics, pulleys, reduction relation), if the propeller is pull or push and the maximum diameter available for us.

With these details we can study which propeller is best suited to your requirements and we shall reply as soon as possible, offering you a specific model together with the estimate.

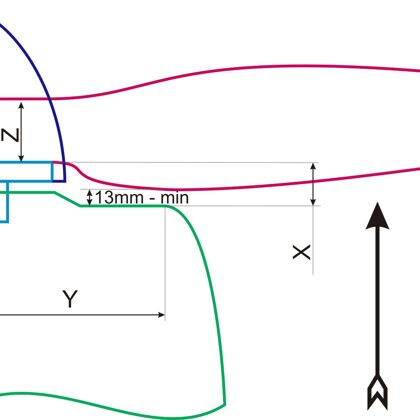

Please let me know when you order the dimensions of X, Y, ZDo not hesitate to contact us: we will assist you as quickly as possible and to the best of our ability.

We work slowly and efficiently. Usually, it takes 1 month to make a propeller. When the production load is high and the queue is formed, the time period increases.

We guarantee high-quality manufacturing and packaging of the parcel when sending it to the customer. However, we cannot be held responsible for the operation of postal services in the event of damage or loss of a parcel during delivery.

Recently, we have organized additional production of decorative propellers. The dimensions could be from 0.5 to 2.5 m. Prices are significantly lower than for working propellers.

When the propeller spins, the tips should pass through the same point with a maximum deviation of 3 mm. To make an adjustment of 1 to 2 mm you can intentionally reduce the tightening of the bolts beside one of the blades, and then excessively tighten the opposite bolts. You must then tighten the first bolts (which will have loosened slightly) back to the “normal” tightening position.

Here is a link; it is in french,but written by Mr Colomban. His method is vary affordable and very useful:http://acversailles.free.fr/documentation/08~Documentation_Generale_M_Suire/Moteur/Puissance/Mesure_de_la_puissance/Mesure_puissance_moteur(M.Colomban).pdf