Dear sirs!

I want to offer you our aviation production from Ukraine, intended for ultralights.

Our production includes wooden and composite propellers under the brand name "Meglin" with straight and saber shape for ultralight and Light Sport airplanes, trikes, paragliders etc.

This production is in good and steady demand in Russia, Germany, France, Italy, USA.

I hope something will seem useful for you too.

Composite propellers characteristics are:

- high performance

- low noise

- minimum vibration

- easy replacement of damaged blades

- low price

Delivery information:

- the cost of sending of this propeller makes usually about 40-60 Euros and transfers separately, after its specification;

- term of performance of the order makes usually 4 weeks without transfer;

- the propeller is sent to you only after reception of money to my account or transfer Transferwise, TransferGo, Swift, WU, RIА, Manigram;

- the manufacturer is not responsible for the operation of postal services in case of damage or loss of the parcel during delivery.

Fans for wind turbines are made on the basis of any propeller. They are have exactly the same appearance and form. However, their toughness is much lower. Installing them on the internal combustion engines is strictly forbidden!

Composite Propellers CR/L (R – right, L – left)

Propellers VL are made of composite materials with usage of the newest technologies. These propellers are equipped with blades straight shape. The great experience of our experts provides high quality and reliability of propellers. The blade's forward edge is protected by stainless steel that prolongs term of service of propeller.

Composite Propellers SR/L

The authors of the scimitar-shape propeller - Kharkov engineers A.Vasilev and P.Dimitrov. Propellers production is 1995. Original design called VN-3 "Donchak." Currently, production is concentrated in Kiev and Kharkov.

The Properties of this propeller are:

- plenty of carbon fibers in blades

- extremely small weight and the moment of inertia,

- the maximal rigidity of blade,

- minimal level of noise,

- the blade's forward edge is protected by stainless steel, , that prolongs term of service of propeller,

- preservation of the aerodynamic properties with oblique air stream that allows to establish propeller behind the wing.

Warranties

If all the rules of transportation, operation, and storage are followed, the propeller can be used based on its condition without any resource limitations. The operator should conduct a control inspection every 100 hours, with a note made in the propeller's logbook. After every 500 operating hours, the operating time information is sent to the manufacturer.

Manufacturer's warranty - 12 months from the moment of selling.

Manufacturer doesn't is not responding responsible for the exploitation of the AP after the lapse of one of the aforementioned terms or in case of failing to comply with the rules of transportation and storage.

In case of flaw detection, arising through manufacturer's fault during warranty period that making the AP's further exploitation impossible, manufacturer repairs or replaces the propeller at its own expense.

Specified life, durability and shelf life are valid only in case of customer's observance of the rules and conditions of storage, transportation and exploitation.

Manufacturer stores the data of all air propellers and their blades ever produced by it. In case of need manufacturer makes an analogue of damaged blade for replacement in ten-day term, according to its serial number, which a customer reports.

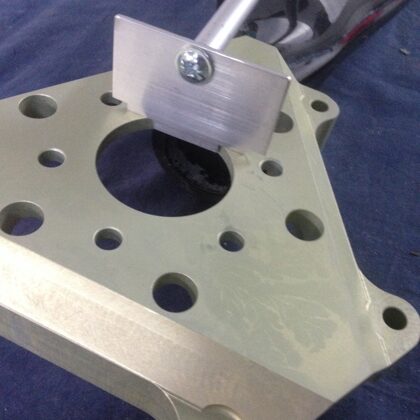

Assemblage

Assembling of the propeller must be realized according to the numbers stamped on every blade and on the hub.

The halves of the hub should be tightened (without an effort) with a help of screws M8 which are in a set of delivery. The halves of the hub must be joined together according to the number inside the hub (facing one another) or according to the pin hole on the cutoff point line of the hub.

An adjustment of the angle of incidence of the blades should be realized with a help of pitch measuring instrument which is in a set of delivery (protractor).

The hub and the blade root are made in such a way, that the blade can rotate round its axle at 360 degree.

Pitch measuring instrument is set in such a way, that the mark "0" of its scale is advisable angle of the blade adjustment. To accommodate the peculiarities of a definite engine, with a definite reduction, it is allowed to change the angle of blade rotation. The most effective is the spread from the curb level of the scale +5 degree.

In the upshot, it is necessary to set such a screw pitch of the propeller under which the engine can develop a promptness mentioned in its passport.

After an exact adjustment of the angles of blades rotation, the halves of the hub must be tightened with tie-bolts. The tightening torque of the fixing bolts M8 is 2.0 kg*m

Setting

An assembled propeller should be tied to the engine's flange. An effort of fastening of tie-bolts of the propeller to the engine's flange - 2,3 kg*m

All of the tie- and assembling bolts should be locked.

Here is interesting information about the testing of propellers, including very expensive ones: https://www.stolspeed.com/nid/46

Here you can read about the variable step propellers that use our blades: https://www.letecka-skola-vysocina.cz/en/engineering-and-production-of-aircraft-engines-and-in-flight-adjustable-large-diameter-propellers/

Please, do not rush. Carefully review all (6) pages of the album. It is possible that you will find something interesting. I am happy to answer questions about each photo.